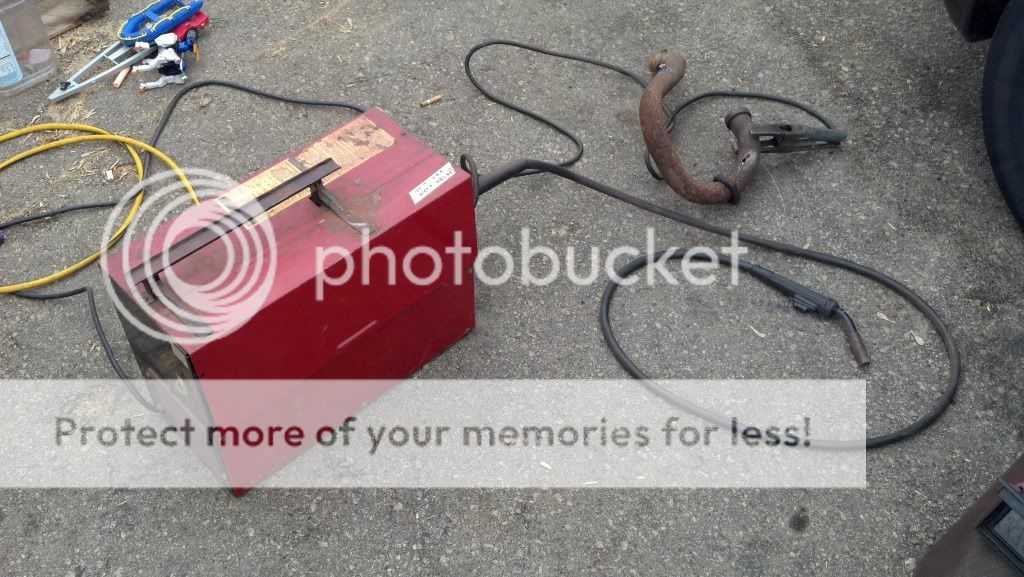

i also have a clarke mig. cost me 250 bucks, and i made a living for over a year with it while i was laid off...

that welder will do EVERYTHING you need it to do using flux cored wire. my clarke will do 1/4 single pass no problem, because i know how to use it. it can do 3/8 if i bevel right and pre heat. but truthfully i will never have to. i do a lot of custom stuff on jeeps and quads, and nothing should ever be more than 3/16 of an inch thick. jeep frames were only 1/8th inch boxed tubing. a lot of the time, guys get carried away with over kill, i don't. i may add an extra brace or something, but that extra brace of 3/16ths is still lighter than the whole thing built out of 1/4 or more.

just take your time and get to know the machine. congrats on a good buy! hope ya like it!