Ok here is what I did to repair my stem:

I got some 1/8" wall tubing that had the same OD as the original stem. I machined a step on the end of the thick wall tubing so it would tightly slide inside the original tube. I cut a taper on the edge for the weld to penetrate. I then cut the tube so that the total length would match the original length. Here is where a guy could make it longer if he preferred the bars to be higher, or shorter if he preferred the bars a little lower. I then cut the weld out of the top of the bar mount and machined the thick tubing so it would press inside the bar mount. I gave it roughly .001" press fit and pressed it in place. I then welded the bar mount to the new tube. I then slid the repair piece into the original stem and lined up the bar mount with the tie rod mounts so they were square with each other. Pretty easy just let the tie rod mounts settle flat where both are touching the bench and turn the bar mount so the flat side is against the bench. I then put tack welds 180 degrees apart, Checked it for straight and tweaked it till true. I then welded alternating sides and checking for straight as I went. Too much heat will warp it and all will be a waste of time. As I said, when done it was within .005. You can see a couple of spot where I pressed on it, but they are away from where it rides in the upper mount. Once the plastics are on you only see the top and bottom anyway.

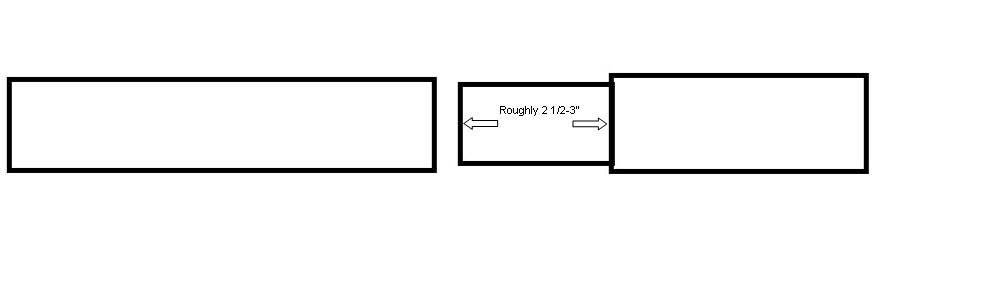

The arrow shows roughly where the upper mount hits in relation to the repair weld. The glare on the black paint makes it hard to see the weld, It isn't the prettiest weld but gets the job done. After I welded it, I chucked it in the lathe and cut the weld back down close to flush. Since I had tapered the end of the thick wall repair shaft, there is plenty of weld still penetrating both parts.

Here is a shot of the lower part and you can see why it would not be any easier to just weld in a new tube. The octagon shape is formed into the tube from the factory so you would have to cut right above it and do the same thing I did higher up on the tube. Depending on how the tie rod part mounts into the tube, a guy might be able to cut the weld and insert it into a new tube. I don't know that the octagon portion would have to be there. I never really looked at it till now, but if a guy had access to a lathe to cut the bar mount weld and the tie rod mount weld, he could probably just put in a new tube and weld it up. Sure would beat the hell out of buying a new stem at several hundreds of dollars.

Before I assembled and welded the repair shaft to the original, I had welded the bar mount to the top of the tube then machined the inside back to the origanal size so the nylon plug would fit back in the top. I put a little silicone on the plug before driving it in to seal any water from getting down in the tube. I later noticed other stems had a solid metal plug welded in the top, and wish I had done that instead.

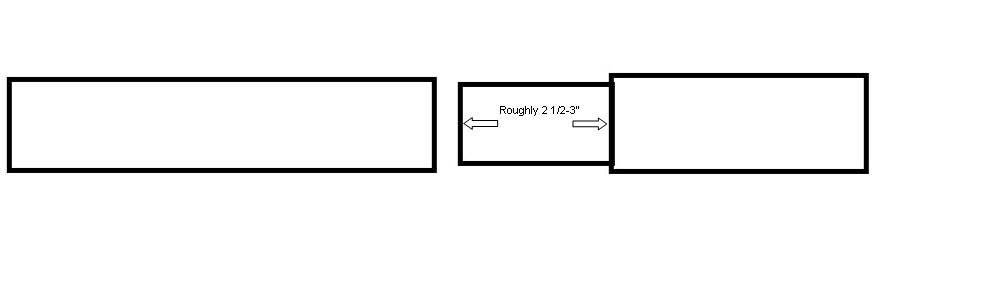

I had gotten a frame that had a straight stem and used that stem. It was an 87 frame and I discovered the bottom where they go into the frame was different. I made a bushing to be able to use it in the later ball bearing style lower mount. Here is a pic of that:

Later I took the bent stem and did the above repair and it is my spare in case I ever bend the one on the ATV now.