251-01 YAMAHA 500 TT/XT/SR VERNIER CAM SPROCKET 252-01 YAMAHA 250 TT, 350 WARRIOR CAM SPROCKET INSTRUCTIONS

The MEGACYCLE CAMS vernier drilled cam sprocket provides nine equally spaced drive pin holes to allow precise installation of the camshaft in a Yamaha 500 single engine. To utilize this sprocket, proceed as follows:

STEP 1: Install the cam using the stock pin hole, marked “S” and the stock timing marks. Measure the valve timing using whatever method you prefer. The method you use to “degree” the cam is not important, as long as you use it consistently.

STEP 2: After comparing the observed valve timing as measured in Step 1 with the desired valve timing, decide how much you would like to advance or retard the cam. It is possible that no change will be necessary. Remember that you can not alter the intake timing without a corresponding change in exhaust valve timing and vice versa.

STEP 3: Once you have decided how you would like to move the cam, use the attached chart to select the alternate sprocket drive pin hole and timing mark which will come closest to providing the desired change. The nine pin holes in conjunction with the thirty-four sprocket teeth will allow you to come within ± 1.2 crankshaft degrees of any desired location.

STEP 4: Install the cam using the new drive pin hole and timing mark. Recheck the valve timing. You should now have the desired timing. If, for some reason you wish to further alter the timing or the desired results were not achieved; repeat the procedure from Step 1.

It is very important that the surface where the sprocket rests on the end of the camshaft be very clean and free of any grit or foreign matter. The sprocket locating pin must be securely pressed into the cam and the bolt which tightens the sprocket onto the cam MUST be tightly in place. It may be necessary to use a small amount of “Loctite” to secure the bolt after you have decided which drive pin hole you will be using. The lip (or flange) which guides the bolt and holds the sprocket in place is delicate. Be careful not to chip or crack this lip. If damage does occur, the sprocket can easily become misaligned and cause problems.

Thank you for buying a MEGACYCLE product. If you need assistance, call between 9:00 PM and 5:00 PM Monday to Friday.

62

90 MITCHELL BOULEVARD „„ „„ „ SAN RAFAEL, CALIFORNIA 94903 „„ „„ „ 415 472-3195 „„ „„ „ FAX 415 472-1497

www.megacyclecams.com

Apr 10, 2012

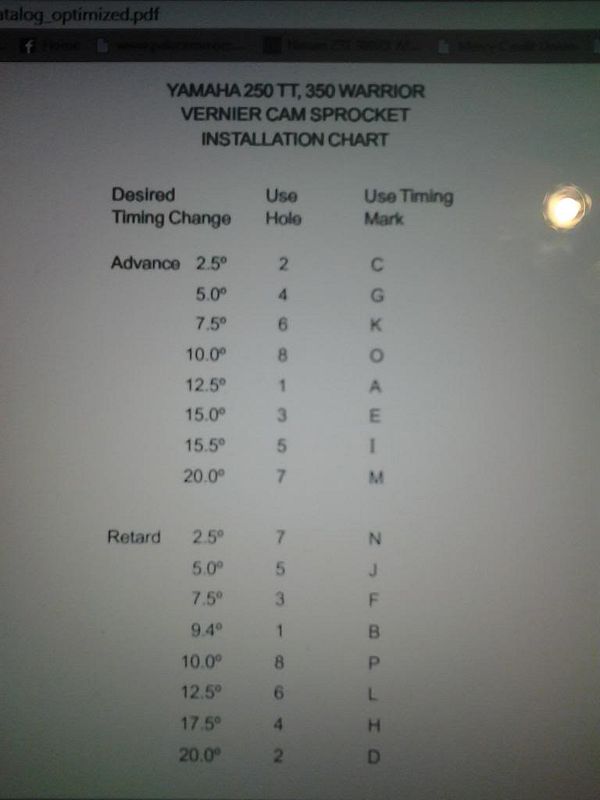

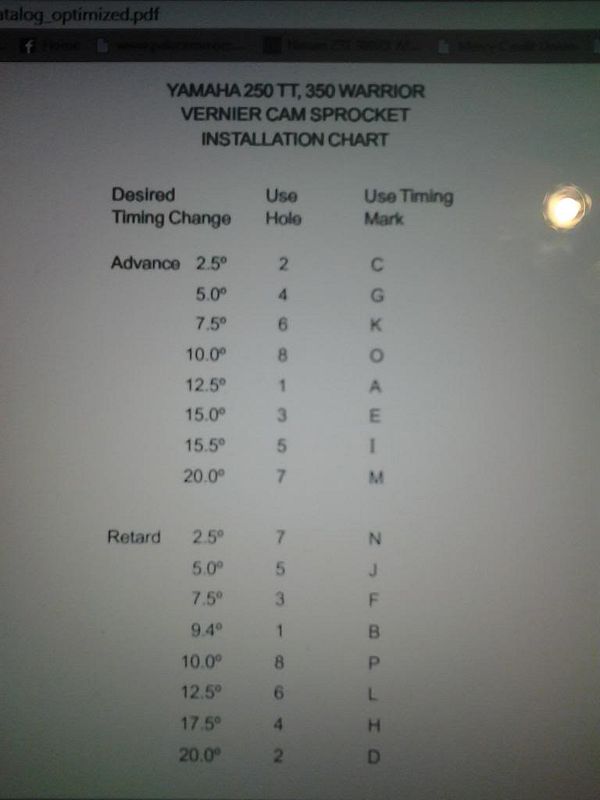

YAMAHA 250 TT, 350 WARRIOR VERNIER CAM SPROCKET INSTALLATION CHART

Desired Use Use Timing Timing Change Hole Mark

Advance 2.5º 2 C 5.0º 4 G 7.5º 6 K 10.0º 8 O 12.5º 1 A 15.0º 3 E 15.5º 5 I 20.0º 7 M

Retard 2.5º 7 N 5.0º 5 J 7.5º 3 F 9.4º 1 B 10.0º 8 P 12.5º 6 L 17.5º 4 H 20.0º 2 D