coryv4

Well-Known Member

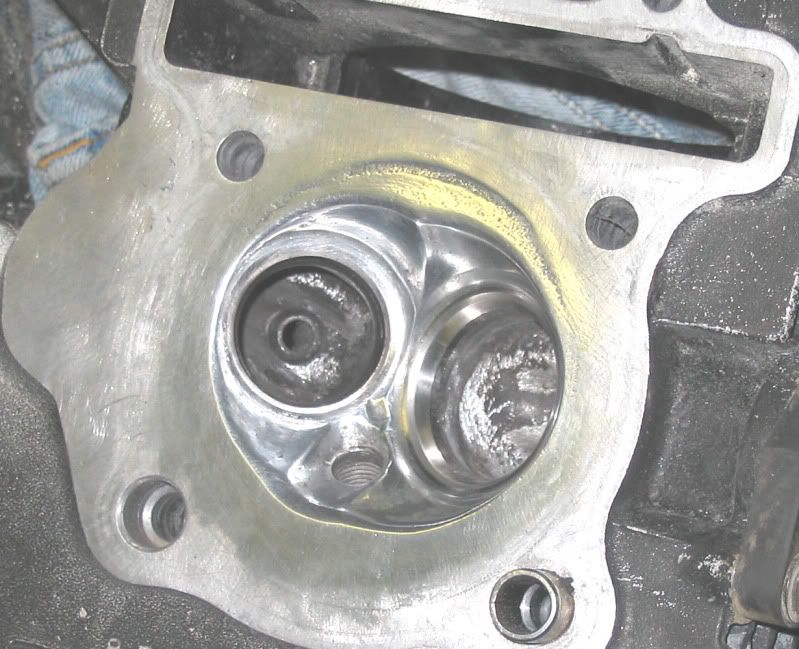

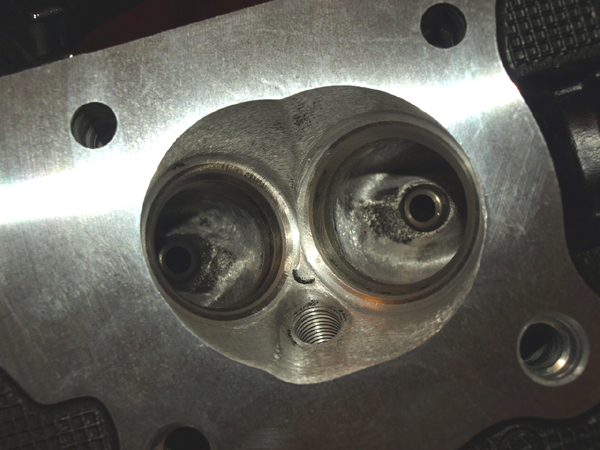

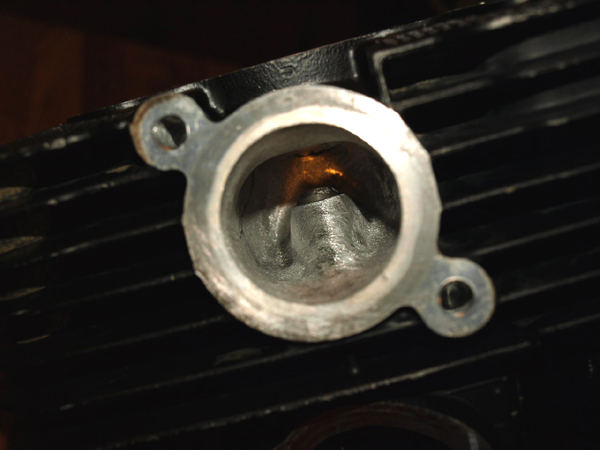

Ok today i am going to be porting my warrior head there are a few things ive noticed as flaws in the intake manifold its not centered. i am going to smooth the exhaust to the best my tools will allow me to next i am going to clean the carbon out of the intake and use a 80grit stone and ruff it up at low speed and run a 320 sand stone in the valve pocket to smooth that out